It gives us great pleasure to announce the

official operational launch of our fully automatic bread production line at the Indonesian factory—a milestone that not only advances our global expansion journey but also sets a new standard for bread manufacturing efficiency in the region. At the core of this high-performance line lies a suite of specialized equipment designed to optimize every step of the dough preparation process: the

Fully Automatic Professional Dough Divider,

Professional Dough Divider & Rounder, and

Professional Dough Portioning Machine. These tools are the backbone of our production system, ensuring precision, consistency, and speed from raw dough to finished loaves.

Built with cutting-edge technology, our Indonesian bread production line is specifically engineered to meet the surging demand for high-quality bread across Indonesia and neighboring markets. A key factor driving its performance is the integration of our professional dough equipment:

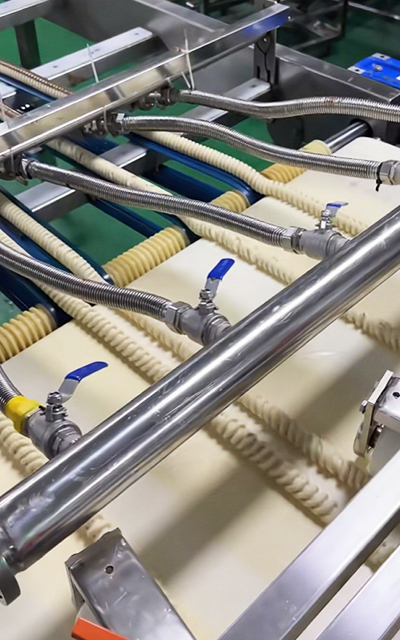

The Fully Automatic Professional Dough Divider eliminates manual errors by precisely dividing large batches of dough into uniform portions, a critical step for ensuring consistent loaf size and texture.

Complementing it, the Professional Dough Divider & Rounder streamlines two essential processes in one: dividing dough and shaping it into smooth, round portions—reducing production time while enhancing the final product’s appearance and structure.

The Professional Dough Portioning Machine further refines accuracy, ensuring each dough portion meets exact weight and size specifications, which is vital for maintaining quality standards at scale.

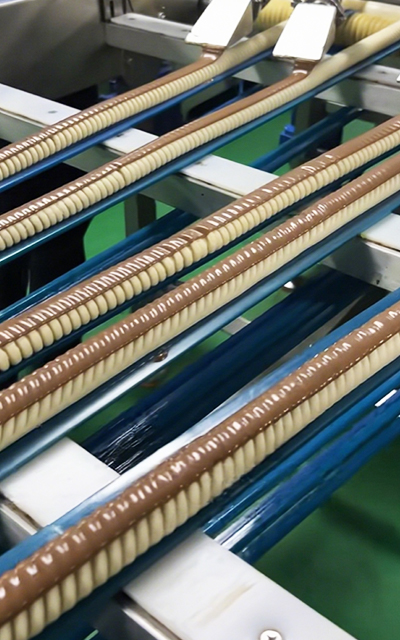

This equipment synergy, paired with the customer factory’s round-the-clock operation, guarantees continuous, streamlined production. Thanks to this intensive work mode and our professional dough tools, the daily bread output hits roughly 800,000 pieces—an impressive figure that reflects not just the line’s advanced tech, but also the reliability of our Fully Automatic Professional Dough Divider and complementary machines in powering high-volume manufacturing.

Bringing this production line to life took months of hard work, detailed planning, and tight collaboration between our team and Indonesian local partners. A major focus of our investment was on top-tier equipment—including our Professional Dough Divider & Rounder and Professional Dough Portioning Machine—and rigorous quality control measures. Every component of the dough preparation process is monitored to ensure consistency: from the Fully Automatic Professional Dough Divider’s portion accuracy to the final loaf’s taste, freshness, and safety. This commitment means consumers in Indonesia can enjoy bread that meets global quality standards, batch after batch.

We believe this new production line—powered by our Fully Automatic Professional Dough Divider, Professional Dough Divider & Rounder, and Professional Dough Portioning Machine—will do more than strengthen our foothold in the Indonesian market. It will also create additional employment opportunities for local workers (including roles in operating and maintaining our professional dough equipment) and contribute to the local economy’s development. This launch is a testament to our confidence in the region’s growth potential and our promise to deliver exceptional products to customers—backed by equipment that combines innovation and reliability.

As we move forward, we’ll keep monitoring and optimizing the production process—with a focus on enhancing the performance of our Professional Dough Portioning Machine, Fully Automatic Professional Dough Divider, and other key tools—to boost efficiency and quality even more. We’re excited about what the future holds and look forward to using this outstanding, equipment-driven production line to bring more delicious, high-quality bread to consumers across Indonesia and beyond.

WhatsApp

WhatsApp Phone

Phone E-mail

E-mail

Comment

(0)